Product Information

NPK 75

NPK 75

- Is a liquid concentrate containing up to 78 chelated natural trace minerals, combined with additional macro and micronutrients – averaging from 100 to 900 nanometers manufactured from natural and chelated trace minerals from mineral rich deposits located in the US and in Eastern Europe.

- Utilizes a proprietary technology and equipment (“NPK 75 equipment”) which can produce 275-gallon plastic totes derived from micron-sized, pre-chelated Montmorillonite trace minerals (“Mineral Powder”) provided by NPK 75 to the production facilities.

- Is a natural climate safe solution that results in almost zero water waste and very little solid waste and no harmful by-products during production compared to NPK chemicals manufactured from petroleum which require thousands of gallons of water and produce harmful by-products.

- Costs significantly less per acre than synthetic and other organic alternatives.

- Requires significantly fewer applications per growing season (3).

- Can be applied as a foliar spray or directly to the soil.

- Has much broader coverage per acre (1 gallon per acre) than other types of synthetic fertilizer.

- Can fully replace NPK as a fertilizer solution or can be used to reduce NPK applications.

- It actually rebuilds the soil over time by stimulating the growth of naturally occurring biologics (microbes) in the soil that reduces the need for pesticides, reduces water usage, shortens the growing season and increases plant growth over time.

- Has a proven increase in crop productivity of 50% or more based on research done by the renowned Pryanishnikov Institute of Russia.

- Provides a complete solution to the current worldwide agricultural and humanitarian crisis.

Verification

a. Demonstrated track record of performance of technologies

The performance of the patented has been tested by farmers in the U.S. in 2020 and 2021 and researched by the renowned Pryanishnikov Institute of Russia in 2021/2022. U.S. farmers anecdotally report that NPK 75 resulted in increases of crop production of up to 50%, a shortened growing season (enabling farmers to get in an extra crop), reduced use of water and pesticides.

The research conducted by the Pryanishnikov Institute on spring wheat and spring barley was conducted in the soil-climatic zone and venue: turf-podzolic heavy loamy soil, 1st agroclimatic zone on the experimental fields of the Federal State Budgetary Institution “VNII of Agrochemistry” in the Moscow region, Domodedovo micro-district. Barybino. The Institute compared NPK 75 to a control crop using no fertilizer, the second crop comparison was to traditional NPK fertilizer.

The Pryanishnikov Institute determined the following from their tests: “[NPK 75] triggers and activates germination initiation mechanisms in all treatments [wheat and peas]. Plants respond to exogenous exposure to NPK 75, changing the physiological and biochemical status – increasing the synthesis of chlorophyll pigments and reducing the intensity of oxidative processes in the body, which helps optimize growth function, provides an earlier start of photosynthesis, which in turn contributes to better rooting, development of the primary root system, better use of soil moisture.”

Palomar Labs study of the use of NPK 75 ON CANNABIS CONCLUSIONS:

- NPK 75 realized a significant overall increase in yield at the 4 oz/gallon treatment rate

- Yield: Flower size and yield increased with the treated plants increased by 18%.

- Flower Size: Bigs increased by 17.88%

- Potency: Values did not change from the treated to untreated samples.

- Terpene: Concentration from the control to the treated samples increased by 9.75%

- Nutrition Stability: The variance in essential nutrient concentrations were limited with treated plants vs. untreated.

Cost Comparison Benefits:

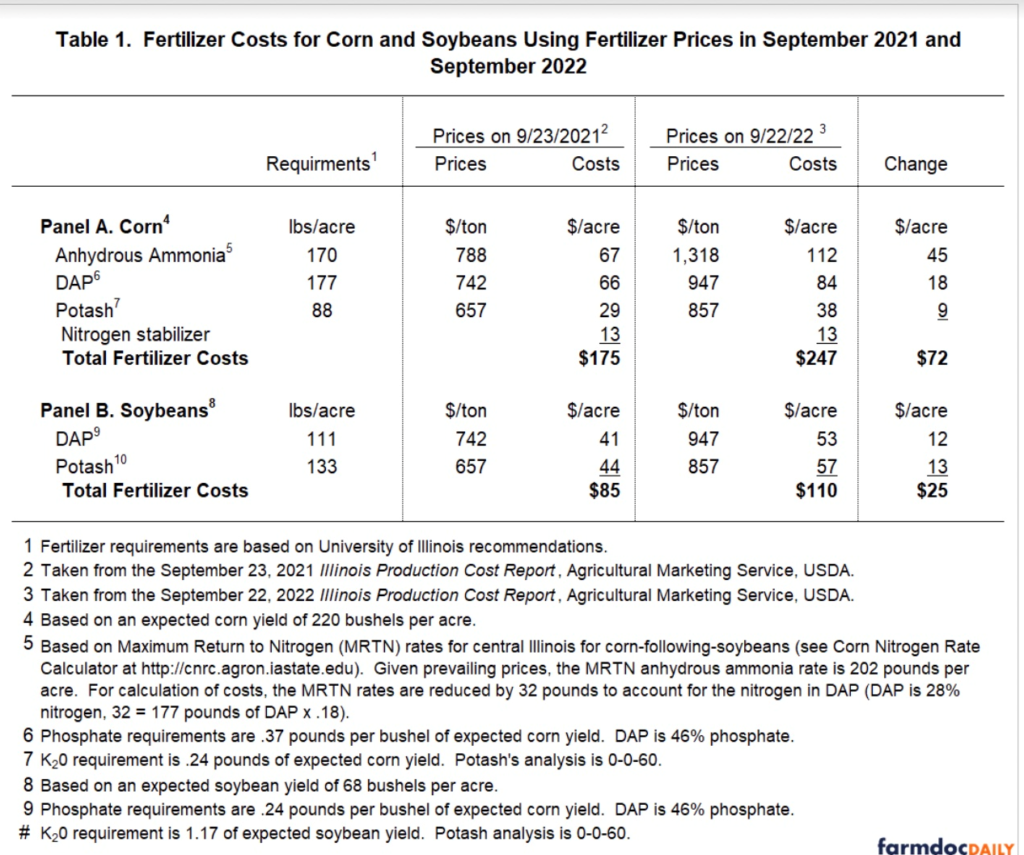

This table provides a cost analysis of the use of synthetic fertilizers. Based on the table, the average cost of fertilizer per acre for corn is $247 and for Soybeans it is $110. Potatoes require about $1,800 per acre on average.

Compared to synthetic fertilizers, NPK 75 costs $100/acre for corn with 4 applications and $50 for soybeans with 2 applications required. For potatoes, NPK 75 is $200/acre, without the harm caused by the high concentrations of under-utilized nitrogen, resulting in green-house gas emissions from nitrous oxide and harms through impacts on water-based ecosystems.

Differences: NPK 75 is 40% of the cost of synthetic fertilizers for Corn, 45% of the cost of synthetic fertilizers for soybeans, and 11% of the cost of synthetic fertilizers for potatoes.

The cost comparison alone is enough to warrant adoption as a total replacement or a partial replacement of traditional synthetic fertilizers.

Market Impact and Opportunities

a. Adequacy, plan and mechanisms for input procurement

NPK 75 is made from mineral rich deposits of chelated trace minerals in the US and Eastern Europe. The deposits contain up to 78 active chelated trace minerals. The minerals are first micronized into a powder.

The micronized mineral powder is then taken through a patented wet process where it is nano-sized and put into a concentrated liquid form and shipped to distributors in 275-gallon totes.

NPK 75 is able to deliver the mineral powder to wet plants as they expand to process to liquid concentrate in 275-gallon totes. It may be that some shipments are handled by rail (if available) depending on the needs of distributors. The cost of a driver and operation of the truck are included in the financial analysis for the project.

b. Current and anticipated number of agricultural producers benefiting from the project

The unique characteristics of the pre-chelated nano-sized Montmorillonite 78 trace minerals in the NPK 75 means they can be absorbed directly through foliar application more efficiently than traditional fertilizer chemicals. NPK 75 absorption rate is 95% compared to an 8% absorption rate for NPK fertilizers. That makes their impact on any crop more immediate, with a stronger increase in productivity, and a long-term impact on improving the quality of the soil over time. It also means that this fertilizer only needs to be applied three times during the growing season.

If a plant produces roughly 6 million gallons of NPK 75 per year and 1 gallon treats one acre on average, and if each crop requires up to three applications per growing season, then the production of one wet plant using 6 turbines will successfully treat 2 million acres per year. This will result in the elimination of the need for other fertilizers, or a significant reduction in the need for and use of NPK, less water and lower levels of pesticides. This represents a higher and disproportionate impact on the amount of NPK required per acre (20 treatments/crop/200 lbs. per acre) when replaced by Mineral-Gro TNT using only 3 gallons per acre across 3 treatments per growing season.

c. Current or prospective end‐user commitments

Having demonstrated the cost benefit analysis of NPK 75 as a legitimate, natural alternative to synthetic fertilizers, the NPK 75 team is currently working with the larger agricultural producers to move from early adopters to full-scale adoption of this unique alternative as a foliar spray option to traditional NPK products.

Climate Impact and Sustainability

a) Expected type, scale, and longevity of direct benefits from greenhouse gas emission mitigation

Worldwide, ”agriculture is the second-largest source of climate change pollution—and both the manufacturing and application of fertilizer has a heavy emissions toll. Synthetic nitrogen fertilizers (derived from fossil gas) and pesticides (derived from fossil gas and crude oil) both contribute to global warming, biodiversity collapse, and toxic pollution. From a manufacturing perspective, the production of the key component of synthetic nitrogen fertilizers is Ammonia (NH₃) which contributes between 1 and 2% of worldwide carbon dioxide emissions. Ammonia has to be made at a high pressure under high temperatures—meaning it takes a lot of energy to manufacture. Most of that energy comes from burning fossil fuels like coal and methane gas, which give off the greenhouse gas carbon dioxide, the main cause of climate change.

From an application perspective, synthetic NPK fertilizers also produce greenhouse gases after farmers apply them to their fields. Crops only take up, on average, about half of the nitrogen they get from synthetic fertilizers. NPK fertilizer applied to crops release an estimated 450 million tons of carbon dioxide (CO2) per year as a result of only half of the fertilizer being absorbed by crops — equivalent to the total energy system emissions of South Africa. Much of the applied fertilizer runs off into waterways, or gets broken down by microbes in the soil, releasing the potent greenhouse gas nitrous oxide into the atmosphere. Although nitrous oxide accounts for only a small fraction of worldwide greenhouse gas emissions, pound for pound, nitrous oxide warms the planet 300 times as much as carbon dioxide. Agriculture accounts for roughly two-thirds of global emissions of nitrous oxide (N2O).

NPK 75 climate safe, organic nano-sized fertilizer contains 78 trace minerals from its Montmorillonite deposits.

There are two types of greenhouse gas emissions that will be mitigated through the production of NPK 75 as an alternative climate safe and organic fertilizer. The first is the difference in emissions reduced during production of NPK 75 vs. NPK, the second is the reduction in greenhouse emissions because significantly fewer applications are required for each crop, 3 applications for NPK 75 vs. traditional NPK fertilizers and the higher absorption rate and lower amounts of nitrogen in NPK 75 mean less nitrous oxide produce.

b) Expected type, scale, and longevity of indirect benefits from greenhouse gas emission mitigation

Waste by-products are also an issue with NPK fertilizers. Nitrogen production requires extensive use of water and fossil fuels for manufacturing. When used in excess, nitrogen fertilizers can be oxidized and lost to the air as nitrous oxide. Nitrous oxide is a long-lived greenhouse gas that contributes to global warming. It stays in the atmosphere for an average of 114 years and is 300 times more potent than carbon dioxide. Potassium and Phosphorus are both mined ores. Phosphate production generates huge amounts of phosphogypsum wastes, nearly 48 million MTs in 1988 alone. Industry estimates that 5.2 tons of phosphogypsum is produced for every ton of phosphoric acid. Phosphorus processing also produces high quantities of naturally occurring radioactive materials. The environmental impact of potash mining is generally localized to the mine site, and may include the disruption of vegetation and wildlife, as well as large-volume water consumption and contamination. Then all three components (NPK) have to be processed together. This quadruple production process has massive negative impacts on the immediate environment and broader climate change impacts.

NPK 75 has no byproducts, either during mining or processing. The deposits are mined and 100% processed into micro-sized powder in the first step. During the second step, the powder is nano-sized and concentrated in water. 95% of all water is filtered and then used in the final product. The amount of water waste is negligible and safe. The number of by-products of any kind is also negligible and safe.

The secondary indirect benefit of NPK 75 is that it is applied to crops only three times during a growing season at an average of 1 gallon per acre as compared to 20 applications of NPK during a growing season, at 200 lbs. per acre. This increased efficiency, reduces the need for the volume of product, dramatically reduces the use and need for NPK at the level it is being used by producers today.

c) Other (non-greenhouse gas) environmental benefits

The dramatic increase in the use of synthetic fertilizers (NPK) since the early 1900’s has resulted in the depletion of naturally occurring minerals in soils. The Earth Summit concluded in 1992 that “There is deep concern over continuing major declines in the mineral values in farm and range soils throughout the world.” This was based on data showing a decline in nutrient levels over the last 100 years: Europe – 72% decline. Asia – 76% decline, North America – 85% decline. Nanotechnology has the potential to revolutionize the agricultural and food industry with new tools for the molecular treatment of diseases, rapid disease detection, enhancing the ability of plants to absorb nutrients etc.

NPK 75 restores the soil over time, increasing the biologics in the soil, adding back in a wide range of trace minerals, replaces or dramatically reduces the use of NPK, reducing the leeching from the soil that synthetic fertilizers cause.

Performance Metrics

a) Provide agricultural producers with more domestic options for fertilizer and nutrient alternatives.

NPK 75 is a climate safe alternative, can be applied as a foliar spray that is immediately absorbed and accessed at a cellular level through the surface/leaves of plants, that is less expensive, requires fewer applications, eliminates leeching and other harms to the soil, decreases the use of water and pesticides, decreases growing season and increases productivity of crop yields by up to 50%. These are all wins for agricultural producers. Getting uptake of a new product that can replace or dramatically reduce the volume of NPK needed, is a challenge.

NPK 75 is a combination product that rebuilds soils over a shorter time frame while maintaining all the benefits described. NPK 75 has already been through two test seasons with US and European farmers and found a high level of support and use of the product. The test sites have demonstrated all the positives about the effectiveness of a nano-sized chelated mixture of 78 trace minerals as a climate-safe alternative for agricultural producers.

b) Reduce the impacts of climate change through the manufacturing and processing of or the use of sustainable, innovative, increased, and efficient fertilizer and nutrient alternatives production and use.

As described above, NPK 75 is an exciting and innovative alternative to synthetic fertilizers. It has no harmful by-products produced during manufacturing; is much simpler and faster to manufacture than tradition NPK; requires only 3 applications per crop cycle; reduces greenhouse gases by reducing the production of nitrous oxide (300 times more harmful that carbon dioxide) from NPK use; and rebuilds the soil while producing healthier crops with more nutrients for consumption.

Environmental Review

NPK 75’s mineral deposits were created over millions of years by a fresh water, stratified sediment largely composed of a montmorillonite, a phyllosilicate – not “silica” and alternating layers of organic material and residual fulvic acid forming a colloidal sandwich Impregnated with a diverse smorgasbord of trace elements chelated to amino acids. (See attachment for the list of trace minerals).

Bentonites and other types of clay can contain overwhelming amounts of certain minerals like silica that could pose potential danger to the system. Montmorillonite is purer with much less calcium and sodium and greater exchange capacities. Its ability to adsorb and absorb toxins makes it the most preferred species of edible clay. “Calcium-based clays are referred to as ‘living clays’ as they principally consist of minerals that contribute to the production of enzymes in all living organisms. They are the preferred clays to be ingested by humans, animals, and plants and for incorporating into soil.” http://www.aboutclay.com/history_of_clay.

Montmorillonite has demonstrated benefits for humans and animals. For plants, the benefits include: Increased yield, bigger plants, more blossoms = more fruit, larger fruit, longer growing season, higher protein count, better nutritional value, reduces wilting during heat and dehydration after harvest, thwarts fungus attacks, increases resistance to other parasites. The montmorillonite helps: foster pro-biotic life that can actually free up nutrients enhancing their bio-availability, break down toxins, turning them into usable elements later on, and bind nutrients to soil particles for easier absorption.

The NPK 75 deposits provide the source of the climate-safe natural fertilizer patented as . There are no harmful components in the inputs (montmorillonite) and no harmful by-products that result from the micronizing and nano-sizing of the deposits. The only environmental issue that a NPK 75 fertilizer production plant needs to address is the potential for mineral dust while the powder is being transferred into the turbines. The end product is a concentrate of the minerals in water. 99% of all water used to make the concentrate is contained in the final product. The plant produces almost zero mineral product waste or water waste. And any waste produced is made up of safe, non-hazardous materials.

As a result, the facility maintains a ventilation system and workers use N-95 filters while transferring mineral powder into turbines during production. The following citation from the EPA’s Identification and Listing of Hazardous Waste 40 CFR §261.4(b): Exclusions: Solid Wastes which are Not Hazardous Wastes.

§261.4(b)(7) Mining and Mineral Processing Wastes (Bevill)

(i) For purposes of Sec. 261.4(b)(7) beneficiation of ores and minerals is restricted to the following activities; crushing; grinding; washing; dissolution; crystallization; filtration; sorting; sizing; drying; sintering; pelletizing; briquetting; calcining to remove water and/or carbon dioxide; roasting, autoclaving, and/or chlorination in preparation for leaching (except where the roasting (and/or autoclaving and/or chlorination)/leaching sequence produces a final or intermediate product that does not undergo further beneficiation or processing); gravity concentration; magnetic separation; electrostatic separation; flotation; ion exchange; solvent extraction; electrowinning; precipitation; amalgamation; and heap, dump, vat, tank, and in situ leaching.

The NPK 75 Climate Smart Fertilizer Plants will meet all environmental and OSHA requirements. Due to the safe and efficient nature of the production of NPK 75, there are no harmful waste by-products (either water or solid waste).

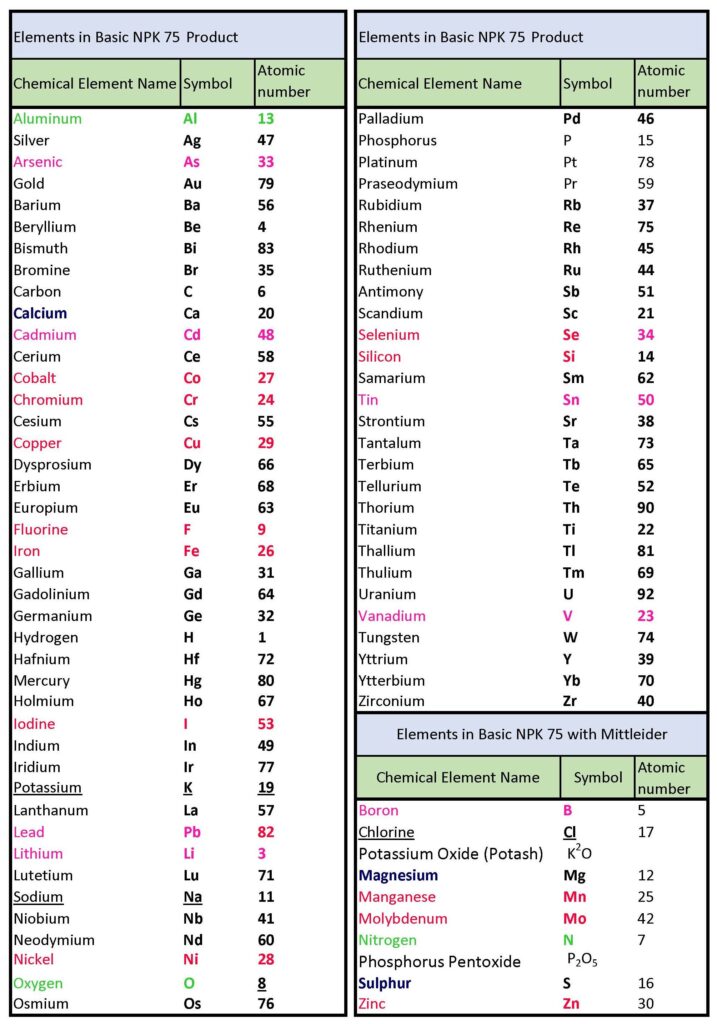

Contents of the NPK 75 fertilizer:

78 Trace Minerals that replenish the soil and improve the nutrition of crops produced.